Wood Gasification

- Bill Wilson

Why Wood Gasification is part of This Permaculture DesignWood Gasification is the process of converting wood (any kind of scraps or trimmings) into flammable gasses by burning it at very high temperatures in an oxygen starved environment. These gasses, once cooled and cleaned of tars, can be piped directly into an internal combustion engine as a fuel substitute for gasoline…!!! We have designed in the use of wood gasification units for:

And the wood gasification units burn much, much cleaner than wood stoves because of the high temperatures. They actually burn off almost all of the smoke and gasses, turning even these into additional energy. |

|

Wood Gasification Explained – Harvested by plants and stored in wood. We learned about wood gasification at the MREA Energy Fair in Stevens Point, WI several years ago. The good folks at Sustain Jefferson had their newly-built downdraft wood gasification unit on display and were sharing about its use and function. The converting of biomass (mostly wood) into what is known as syngas (synthetic natural gas) has been around for over 100 years but was mostly forgotten once gasoline become readily available and inexpensive in our culture. Who wants to go to the trouble to start a fire in the back of their car or truck when with gasoline, all we need to do is turn a key. But as recently as WWII, over 1,000,000 vehicles in Europe were converted from burning gasoline to burning wood when gas became almost impossible to obtain. It has been said that the German army had to convert many of their military vehicles, including tanks, to the burning of wood so that they could retreat at the end of the war. As liquid fuels continued to be a challenge to obtain in Europe, sleek new designs were developed for affluent drivers. Woodgas was one of the key available fuel sources at that time. But once petroleum become abundant and cheap, wood gasification became a thing of the past. Today however, as gas prices continue to rise and as even its future availability seems less certain, many do-it-yourselfers are looking seriously at wood gasification as an honest and environmentally sound alternative to petroleum.

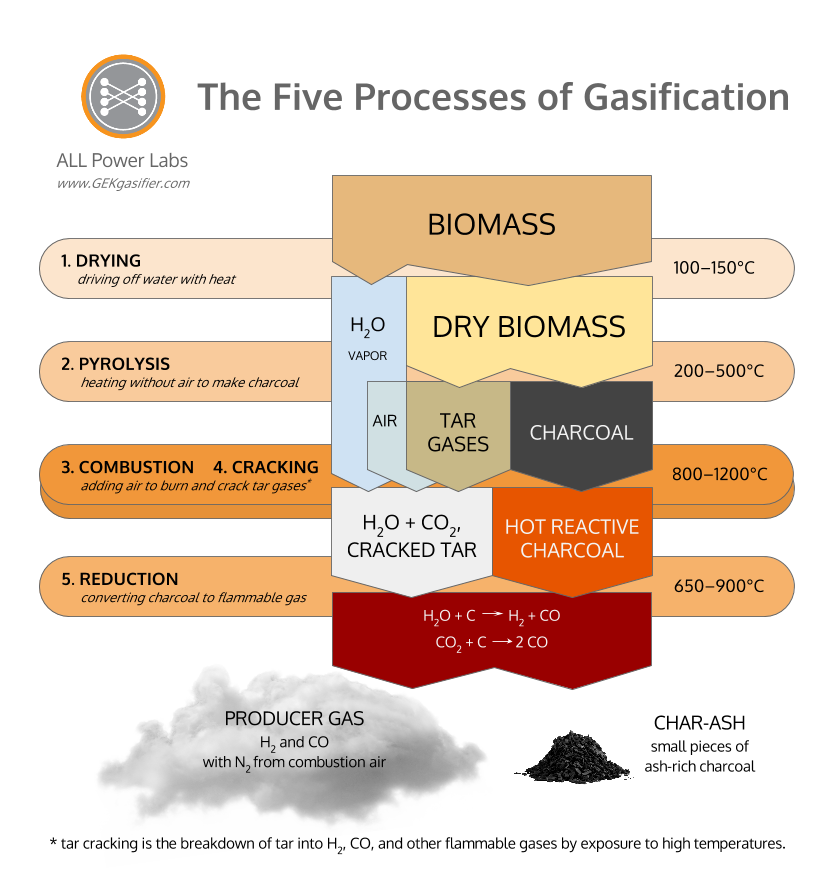

How it WorksThe process of burning biomass at very high temperatures in an oxygen starved environment to pull off hydrogen (H2) and carbon monoxide (CO) is knows as pyrolysis.

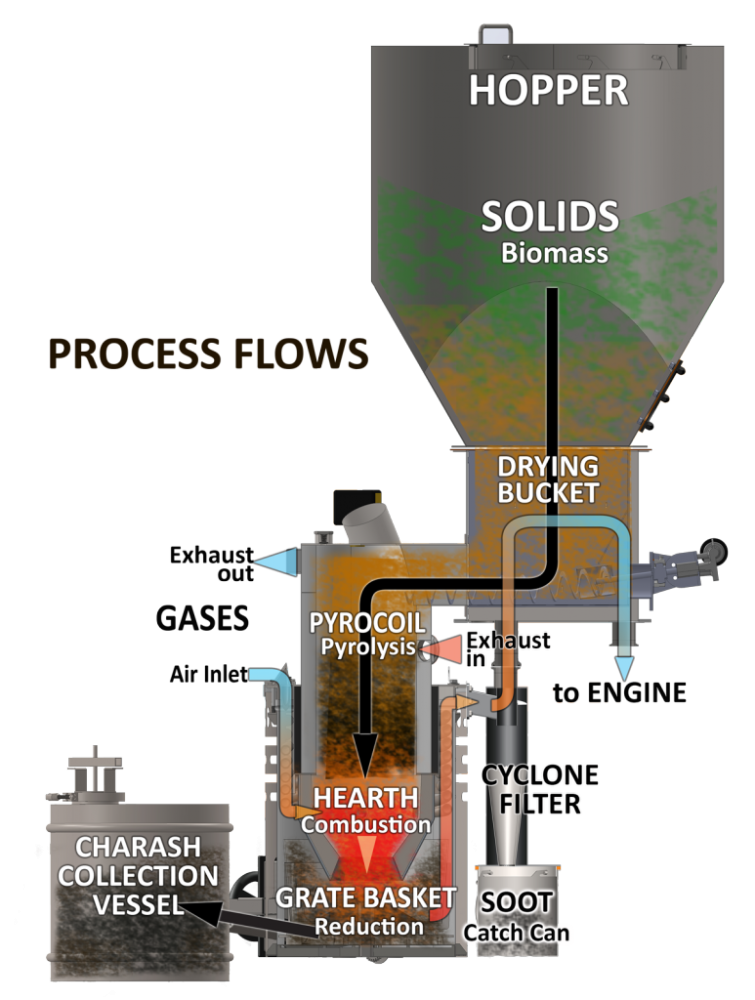

The folks over at All Power Labs have a great website that explains this graphic in full detail. The gasification units or ‘generators’ can be made in a surprising variety of ways but here is a cross sectioned diagram of a unit also developed and found on the All Power Labs website.

The point is… we are not inventing a new technology, but with the tools and materials we have available to us today, building gasification units is a very real alternative for many people and situations. For Example

At the time of the article, Wayne had been running on woodgas for over 8 years. Here are some of the bottom line results he shared in the article;

Does it Really Work? Let’s take this in steps.Since I had never seen an engine running on the burning of wood, it was a hard thing for me to believe. Thanks to YouTube and those willing to share, one can find an abundance of examples now. Recently, I took our interns and a friend up to Wisconsin to meet Ben Hansen to learn first-hand from someone who has built and used several units. While we were there, Ben had us help him take apart one of his wood gasifiers that needed cleaning and maintenance. Afterwards we put it back together and fired it up. Amazing…! It really produced flammable woodgas. Our friends up at Sustain Jefferson in Wisconsin also have a series of videos up on YouTube that share their journey as well. Here is a short segment I pulled out that shows the starting of a motor from a wood gasifier and the generation of electricity to run a light and a fan (both essential in a winter greenhouse for growing more than just greens).

Here is Wayne Keith himself on a typical work day hauling bails of hay with one of his wood burning trucks. And just so you know, the examples I’ve given you above are of everyday people like you and me, building these units themselves from mostly throw away materials. Their homemade systems costing some as little as $100 and $300 to build. If however you want a professionally made unit for your home, homestead, farm or small business, the folks over at All Power Labs have done an exceptional job. (BTW… we are not distributors for APL…we just really like all of the information they have provided to all of us on their site.) And We’re Using Current Sunlight, Not Ancient SunlightThis means that we can run cars and trucks by burning wood that we grow on our very own site and much of it can be from just two-year-old growth, i.e. brush. We don’t have to wait years for trees to get full sized. We can ‘collect’ the sun’s energy into woody plants in one year and turn it into power just two-three years later. After all, oil (gasoline) is nothing more than ancient sunlight that was stored in plants and buried for millions of years. Why wait…!!!??? For example, hazelnut production benefits from coppicing (cutting the plant off close to the ground) every 7-10 years for optimum production of nuts. Also, any woody biomass or branches from a more mature food forest could be gathered and chipped (or chunked) and burned in a gasifier. Environmental Benefits

But adding to these already significant benefits, the wood generator also produces a fair amount of charcoal, also know as biochar. It is biochar that the ancients used in South America to build the fertility of their soils and boost their crop yields With the use of biochar they turned the pale rain forest soils into a black humus…. terra pretta…!!! And… when we pull carbon out of the air, put it into plants, then lock up some of that carbon into biochar when we burn it, and then put the biochar into the soil…. we are literally pulling Co2 out of the atmosphere and storing it in the soil! Summary – This Is Huge…!!!Follow this thinking, we can design a possible path towards an environmentally sound and humane future — a ‘permanent-culture’ future. Below is a very simplified outline but it hits the highlights.

All Season Greenhouses in our Temperate ClimateFinally, one of the big applications we see for a wood gasification unit is during the winter in a greenhouse. A winter greenhouse needs heat, light and Co2 to produce abundantly in our cold and often snowy winters and a wood gasifier hooked up to an electric generator would provide all three. More on this in the greenhouse portion of our design.

I, for one, am inspired by the creativity and work done by the people we have met who have been experimenting with woodgas and other essential aspects of living in recent years. The real problems of the world will likely not be solved by governments or big business. they will be solved by you and me. Let’s do it! Thanks to Ben, Greg, Rob, Wayne and many others for their efforts.

Bill Wilson — Midwest Permaculture (updated 12/28/15)

|

|

Wayne Keith, a farmer from Alabama, was featured in the spring edition of

Wayne Keith, a farmer from Alabama, was featured in the spring edition of  Gasification is one of the cleanest, most efficient combustion method known. It is estimated that burning wood in a gasifier is 90% cleaner than burning it in a wood stove. A gasifier burns the wood AND almost all of the smoke and gasses turning it into additional power.

Gasification is one of the cleanest, most efficient combustion method known. It is estimated that burning wood in a gasifier is 90% cleaner than burning it in a wood stove. A gasifier burns the wood AND almost all of the smoke and gasses turning it into additional power.

14 thoughts on “Wood Gasification”

We are interested in a wood gasifier to produce wood vinegar and charcoal

Let us know how the process goes!

Just a note from someone who makes woodgas daily – the FEMA gasifier doesn’t produce engine grade gas. Commonly called a “tar maker” in the community. It can work, but you’ll stick up your valves fairly quick.

Hi,

The website with the gasifier design is down, any other sources or site that has the design?

Thx

Richard

Yo Richard…. I found a link where you can download the plans on another page. Thanks for the heads-up too…I fixed the link.

http://driveonwood.com/resources/pdf-articles/fema-gasifer-plans

Have fun…

Interesting! I’m currently reading a SF novel by John Varley called “Slow Apocalypse” which speculates on the results of the world’s petroleum supply suddenly becoming unavailable. Guess what the characters use to power their trucks and buses ?

Wood gasification 😉

Good to hear from you David. It’s so hard to imagine a future without oil when there are seemingly no signs in our day to day life that we are at a critical precipice. So…it’s good to know that there are folks working and writing about a future with less disposable energy. We will need lots of options.

Cheers…Bill

Am converting a one bedroom home with electric heat to a log style home. Main room will get a loft. Master bed room separate. I would like to supplement the electric heat with an efficient wood stove. Preferably one that properly burns the wood gas instead of pumping out the flu.

With that in mind the Mass heater is too large for a tiny bed room and a tiny living room/kitchen. Besides Im only home part of the day so would use electric to keep it say 55 or 60F to prevent pipe freeze an to quickly raise the temps to comfortable 70’s in morning and at night after work with a wood burner. So with that in mind……. what do you recommend? I’ll be burning biomass (summer grass cutting approx half acre worth) and paper logs or bricket from a small schools restroom paper towel waste. Will also have small micro home on site (12×6″ log construction 12’x16′ in size) and want to small biogas burning heater for that too. THANK YOU in advance

not sure it got set to auto recieve replies so I’ll add…

so not having to heat WHOLE house all the time I would think a small heater for the separate master bedroom would be wise along with a second unit in the living room

Hi, Great website. Lots of info. Wish I had some info to give you back. I’m 77 and this stuff has excited me more than it should. HeHe. I have everything to do this except the health. But maybe this will give me a jump start to do something before I buy the farm. Thanks and keep on keepin on. Ron S

Bless you Bill (& Becky)!

I’m working in the city, barely thinking about farms. But your work is CRUCIAL to me. When I meet the folks who say, “There’s NO WAY we’re gonna make it!” I can say, with truth in my heart, “There ARE ways! Look at this!”

Richard

I understand your passion and your relief Richard. I was deeply relieved as well when I saw this path. And I know that it’s not the only path either. There is hope my friend. Great hope everywhere. In the works of Bill Mollison… “Though the problems of the world are increasingly complex, the solutions remain embarrassingly simple. Cheers… Bill W.

Looks great Bill.

Thanks Larry…