Year-Round Greenhouse

- Lizz Shallert

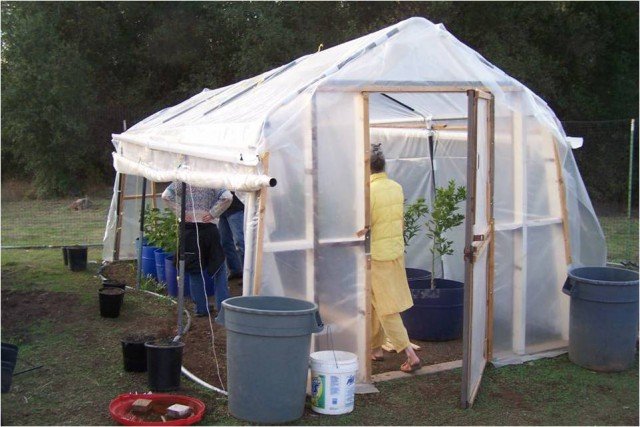

Why A Year-Round Greenhouse is part of This Permaculture DesignIt doesn’t take much for those of us in temperate climate zones to imagine the allure for year-round greenhouses. Fresh tomatoes in January are compelling! A more controlled and protected environment in spring, summer and fall has real advantages as well. And from a small business perspective, what if we could produce enough fresh produce for ourselves and a handful of our neighbors 52 weeks of the year? In a good permaculture design for an urban residence, a homestead or a farm, the first thing we seek to accomplish is the efficient storage of summer crops through root cellaring, drying, fermentation and other forms of preserving. But once we accomplish this… few things beat fresh produce in the middle of winter. To get this done we need to design for the two major demands of plants that are in short supply during the winter months: heat and light. |

|

Year-Round Greenhouse Explained

When looking to efficiently heat a space in the winter we look for ways to store excess heat as it becomes available (sunlight or other heating sources). The way to store this excess is typically in some form of mass or what is knows as a thermal battery. The Thermal Mass Value of different substances gives us some clues to the more ideal materials or substances to use. THERMAL MASS VALUE BTU/Sq. Ft./degree F.

Certain substances, like water and steel, have extremely high TMV, meaning that they store a lot of excess heat compared to earth or soil which hold about 1/3 the amount in the same amount of area. In other words… storing excess heat in the floor of your greenhouse is a great idea, but if you can find a way to store this excess in water you can hold three times more in the same amount of cubic feet. One key to consider is what is easily available and cost effective. Sometimes the earth is our best choice since it is right underneath our feet. So let’s look at 6 ideas for heating and cooling that we might include in our permaculturally-designed, year-round greenhouse.

1) Storing Excess Heat in Water The high TMV, ease of availability, and fluidity of water makes it an attractive possibility. There are many options for directing and storing the warm water throughout the greenhouse to move the heat where it is needed including coiling beneath plant beds, the floor or walls of the greenhouse. Water can be stored in barrels or other containers easy to come by.  Check out this design by Penn and Cord in Westcliffe, CO that uses water as thermal mass in barrels. Be sure to stop by their website at http://pennandcordsgarden.weebly.com/. When we asked them about the results of their design, Penn responded, “Had to share this with you Lizz – these greenhouses work better than we can tell you – and better than the original scientists who figured this out thought – it’s really exciting when it’s blizzarding on the mountain and I am in there warm as toast.”  Another option for using the TMV of water is integrating an aquaponics design into the greenhouse. A large amount of water acts as a thermal battery which more evenly moderates the temperature. If tilapia are being raised then the water needs to be heated in some way for them. The warm water then release some of its heat into the surrounding air, and the nutrients from the fish feed the plants. Ecology by design. Will Allen and his team at Growing Power in Milwaukee are pros at this process. We love his social permaculture work as well which helps so many people in his surrounding community and elsewhere. Learn more about Will Allen’s work here.

2) Greenhouse Glazing Different types of glazing (the cover of the greenhouse) provide different levels of heat and light passage. The term R-Value is a common measure for determining how much heat a substance can hold in. The chart below shows various glazing options along with their corresponding R-Value:

R-Value Measurements (hr°Fsq.ft/BTU)

In comparison to the low insulating values of these glazings, six inches of fiberglass bat insulation has an extremely high R-Value at 19! CertainTeed is a company that uses recycled materials in its Fiberglass. They report that their fiberglass, “will save 12 times as much energy in the first year of use as the energy used to produce it.” Wouldn’t it be amazing if we could find a glazing material that lets light and heat in during the winter months, but does not let the heat out?

3) Soap Bubble Insulation  Harvey Rayner’s Solar Bubble Build in the UK is an innovative approach of using soap bubbles for insulation, providing an R-Value of up to a whopping R-30! This technique requires two layers of polyethylene or other clear sheathing with a 1-2 foot wide cavity. During the day the cavity remains bubble free so that sunlight can penetrate and heat the greenhouse and preferably some other form of thermal mass within. Come evening, a soap bubble blower is turned on and the cavity is filled with millions of tiny soap bubbles, each acting as a deterrent to heat transfer from the relatively warm inside of the greenhouse to the much colder outside. And the water that makes up the soapy solution can also be used as a thermal battery to store some of the excess daytime solar gain (heat) which is then released at night as a warm blanket of bubbles and with the aid of a heat exchanger (various options here). And in the summer, when the sun’s heat is not appreciated or needed in the greenhouse, the soap filled glazing (now filled during the day and not at night) shades the interior just like a cloud breaks the intense heat of the sun when you are out in your garden. It acts as a shade cloth which accepts the spectrum of light in that encourages plants to grow, but not the spectrum that generates heat. A real blessing in the summer’s heat. Just a note of realism and transparency We personally are not aware of anyone using this soap bubble technology in a long-term, high-production system. This does not mean that they are not out there… only that we don’t know of anyone to reference you to. Feel free to send us relevant links or information in the comment section below so we can learn from each other.

4) Thermal Mass Rocket Stoves (TMRS) for Heat Another idea we are planning to experiment with is heating our greenhouse with a Rocket Mass Heater (also referred to as a TMRS) using the surplus wood from our orchard and evolving food forests and hedgerows. Using relatively small branches and other waste wood we can capture the stored sunlight energy within and when burning it in a TMRS we gain the maximum amount of recoverable heat while preventing the associated smoke and air pollution common in traditional wood burning stoves and fireplaces. It is estimated that it takes ¼ of the wood compared to a wood stove and the exhaust is extremely clean… a 90% cleaner burn. More Detailed Description of Rocket Mass Heaters Here Through the reburn combustion chamber in the rocket stove, fire burns sideways, up, and around, as it moves through the stove, releasing heat, clean steam and CO2. A crystal clear burn is the product of these stoves.

5) Wood Gasification for Electricity and Heat A winter greenhouse needs heat, light and CO2 to produce abundantly in our cold and often snowy winters and a wood gasifier hooked up to an electric generator would provide all three!

More Detailed Description of Wood Gasification Here While a rocket stove’s greatest gift is heat, a wood gasifier’s greatest gift is the production of woodgas (also know as syngas or producer gas) which can be fed into a combustion engine to produce electricity or run a vehicle! In a greenhouse this means electricity for light and heat. About 750 Watts of electricity can be generated with a mere 2 pounds of biomass. Pretty amazing! Here is a brief outline of the energy conversion yields: 2 Pounds Biomass (wood) ==> 70 Cubic Feed Producer Gas ==> One HP Hour of Power ==> .75 kWh Electricity (750 watts) So, again the benefits of using wood gasification in a greenhouse design are:

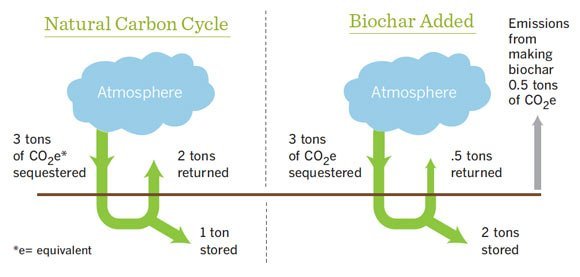

Biochar is a byproduct of the downdraft wood gasification unit when it’s cleaned. Have you heard about all the benefits of biochar? It harvests and locks up CO2 which can be worked back into the soil to help generate better yields and hold the stored carbon for centuries. It’s a soil enhancer that’s been used for 2,000 years! By this method of capturing and storing CO2, we might be able to retard or even reverse global climate change if it is truly caused by excessive CO2 levels in the atmosphere! You can learn more on the ancient carbon sequestering soil amendment, biochar, here, or through the International Biochar Initiative.

6) Earth-Friendly Building Materials Many parts of a greenhouse design can be built using Recycled Materials. Below are some resources for incorporating recycled materials in a greenhouse design:

This Article Co-Written by Elizabeth Schallart and Bill Wilson |

|

Elizabeth Schallart works for On Earth Peace, a nonprofit that provides peace education, social change and conflict transformation across the country. She is also a permaculture practitioner with a love for melding trauma healing and earth care. She earned her PDC from Midwest Permaculture in 2013. |

Bill Wilson is a permaculture teacher, designer, and the co-founder of Midwest Permaculture. |

[contentblock id=10]

Wood Gasification is the process of converting wood (any kind of scraps or trimmings) into flammable gasses by burning it at very high temperatures in an oxygen starved environment.

Wood Gasification is the process of converting wood (any kind of scraps or trimmings) into flammable gasses by burning it at very high temperatures in an oxygen starved environment.

4 thoughts on “Year-Round Greenhouse”

I could use some help asap. I built a wooden frame greenhouse 14×28 & used sun tuff sheet plastic here in north Arkansas to cover the sides and roof. I used heavy ply plastic inside on the rafters to help save on heating cost during the winter. Since then it has fell apart. In replacing it, can I use the sheet sun tuff plastic rather than use rolled plastic again.

Hey Sam! Soon to come is another post on season extenders, and given your hot climate/depending on your specific zone, smaller implements like cold frames (for starts), and tunnels for specific rows may do the trick! Check out that post as it comes up. And Milton is right- ventilation is KEY! It’s easy to overheat plants, especially in a hot climate…so you have to build for vents. Be sure to include a thermometer in whatever you try and monitor it at various points of the day. Have fun!

Interesting uses for greenhouse, especially in holding in heat! Since I live in central Texas with the hot summers, what would be my preferable method for having a year round greenhouse.

I would make sure you have a good way to vent it. You might want a greenhouse where you can roll up the sides, that has good vents, a fan or even a swamp cooler. Anything to keep the greenhouse from overheating. I think the best option would be taking advantage of any passive cooling you can.